Risograph printing, also known as Riso printing or Risography, is a popular and unique form of printmaking that has gained popularity in recent years. This technique was first developed by the Japanese company Riso Kagaku Corporation in the 1980s and has since become a favorite among artists, designers, and small businesses alike.

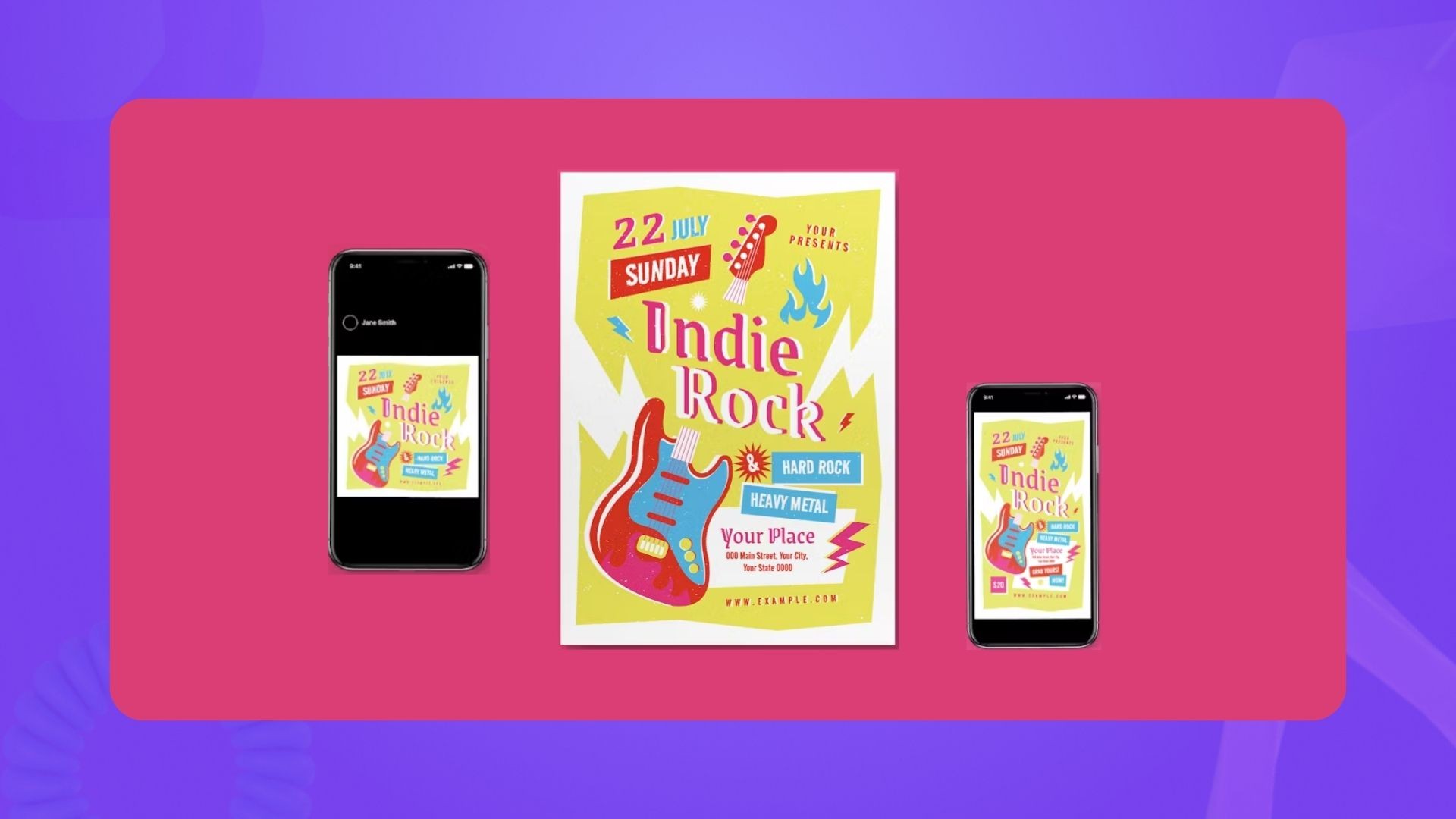

Due to its distinctive aesthetic and relatively low cost, Risograph printing has become a popular choice for creating zines, posters, flyers, business cards, and more.

But what exactly is Riso printing and how does it work? In this article, we will explore the basics of this unique printing process and provide step-by-step instructions on how to create your own Riso prints.

What Is Risograph Printing

Risograph printing is essentially a high-speed digital printing system designed for high volume production. The process combines elements of screen printing and photocopying. The name "Risograph" comes from the Riso Kagaku Corporation, which developed the system. The word "riso" also means "ideal" in Japanese, reflecting the company's commitment to creating an ideal, environmentally friendly printing solution.

One of the distinguishing features of Risograph printing is its vivid, spot colors. Each color requires a separate ink drum, meaning that multi-color prints need to be passed through the machine multiple times. This can lead to slight misalignments known as "registration errors," but these are often embraced by artists and designers for the unique, handmade aesthetic they lend to the prints.

Project by Anátema, https://www.behance.net/gallery/24409609/Anatema-Zine

Project by Dionne Kitching, https://www.behance.net/gallery/182986945/MUSHROOMS

How Does Risograph Printing Work

The Risograph printing process can be divided into several distinct steps. Firstly, the origied into the Risograph machine. The machine then creates a master copy by burning the image onto a thermal plate. This master copy is in turn wrapped around a drum filled with ink of the chosen color.

In the next step, the paper is fed into the machine and as it passes under the drum, the ink is pushed through the holes in the master copy, transferring the image onto the paper. This process is repeated for each color that needs to be added to the print. It's important to note that the paper must be given sufficient time to dry between each pass to prevent smearing of the ink.

The efficiency comes from the fact that once a master copy is made, it can be used to print hundreds, or even thousands, of copies. This makes Risograph printing a cost-effective choice for large volume projects. However, it's also worth noting that due to the manual feeding of the paper and the potential for slight shifts in alignment with each pass, each print is often slightly unique, adding to the charm of the Risograph printing process.

How to Create Riso Prints in 5 Steps

Creating Risograph prints is a relatively straightforward process that can be done with the right equipment and materials. The following tips will help you you started:

Choose Your Design

The first step is to decide on the design you want for your print. This could be a drawing, a digital design, a photograph, or text. Keep in mind that Risograph printing works best with designs that have bold lines and limited colors.

Find design elements and customizable templates here

Limit the Number of Colors

The design can be as simple or as complex as you wish, but each color will be printed separately, so designs with a limited color palette will be easier to manage. Risograph printing can only handle up to 5 or 6 colors per print. This is due to the limited number of drums and ink available for each machine.

Convert Your Design to CMYK

Risograph printing uses the CMYK color model, which stands for Cyan, Magenta, Yellow, and Black. If your design is not converted to CMYK, the colors may appear distorted or different from what you intended.

Work on Layers

To create a multi-colored print, you will need to work on layers. This means creating a separate master copy for each color in your design. It's important to be precise with each layer, as misalignment can occur if the masters are not properly aligned. This can lead to a blurry or miscolored final product.

Choose Your Paper and Do a Test Print

A risograph print works best on uncoated paper, as glossy or coated paper can cause the ink to smear. You can choose from a variety of paper weights and textures, but make sure that your printer is able to handle the weight of the paper you have chosen.

Finally, don't forget to do a test print on your chosen paper before printing a large batch. This will allow you to make any necessary adjustments.

Risograph and Regular Printing: What's the Difference

Colors: One of the main differences between Risograph printing and regular digital printing is the use of spot colors. While most printers mix different combinations of cyan, magenta, yellow, and black (CMYK) to create a full spectrum of colors, Risograph machines use ink drums filled with specific spot colors. This results in brighter, more vibrant colors that are often not achievable through regular printing methods.

Versatility in design options: With most printers, designs are limited to CMYK color combinations and standard paper sizes. However, with Risograph printing, you have a wider range of colors to choose from and can print on a variety of paper types and sizes.

Environmental sustainability: Unlike regular printers that use toner cartridges, Risograph machines use soy-based ink which is biodegradable and eco-friendly. The process of creating a master copy does not involve heat or toxic chemicals, making it a greener option for printing.

Cost-effectiveness: For small print runs, Risograph printing can be significantly cheaper than regular digital printing. This makes it an ideal option for independent publishers or artists who want to produce limited edition prints or zines.

Final Thoughts

Artists, designers, and publishers are constantly looking for unique and cost-effective ways to produce their work. Riso printing offers an alternative method that combines the quality of screen printing with the convenience of digital printing. Its versatility, vibrant colors, and environmentally sustainable process make it a popular choice among creators.

In addition to its practical benefits, Risograph printing also has a distinct aesthetic appeal that sets it apart from regular printing methods.